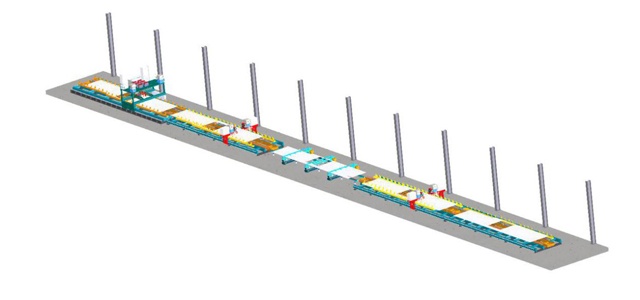

Aluminum alloy container side box robot automated welding manufacturing line automation

Aluminum alloy container side box robot automated welding manufacturing line automation consists of assembly station, side box assembly and side beam welding station, side box manual trimming and flipping station, side beam secondary welding station, side box longitudinal weld welding station, logistics conveyor line and whole line operation monitoring system. The space is 100 meters long, 5 meters wide and 5 meters high. The overall layout is arranged in a straight line and the assembly line operation method is adopted, which makes the overall structure reasonable, convenient for production site management and has high production efficiency.

Application:

Aluminum Alloy Container Side Box Robot Automated Welding Manufacturing Line Automation is widely used in truck compartment welding, refrigerated truck compartment welding, semi-trailer floor welding, new energy vehicle battery box welding, ship welding, mechanical equipment shell welding, aluminum alloy locker welding, etc.